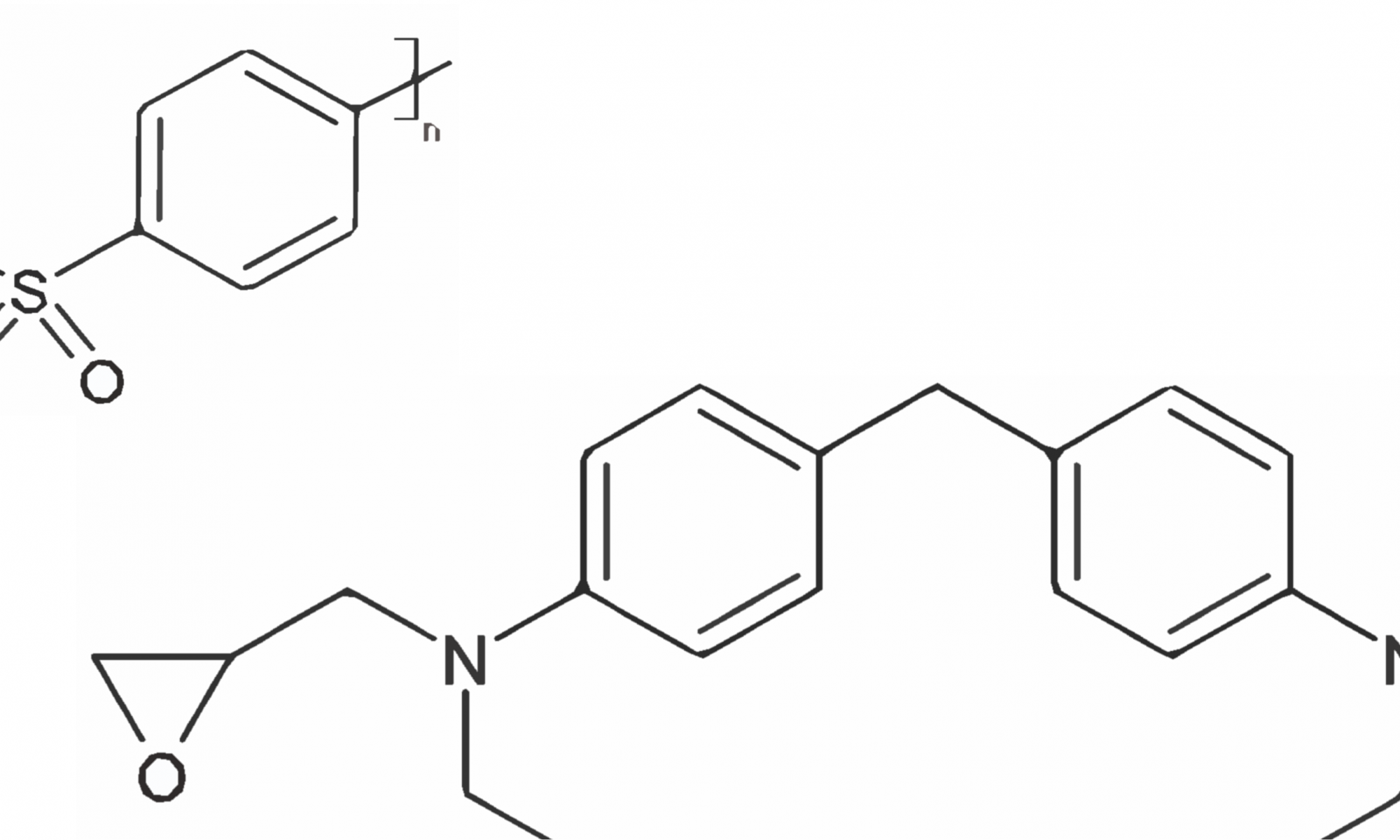

Aerospace-grade prepreg resin films based on multifunctional tetraglycidyl-4,4′-methylenedianiline (TGMDA), triglycidyl p-aminophenol (TGAP), Bisphenol A diglycidyl ether (DGEBA) and curing agent 4,4’diaminodiphenyl sulfone (DDS) are investigated in terms of tackiness by probe testing. The model epoxy systems are modified regarding the thermoplastic toughener content (polyethersulfone, PES) and the B-stage level, which is adjusted by cure prediction based on a model-free isoconversional method (Flynn-Wall-Ozawa). Additional DSC and rheological analysis are performed to study the thermal and viscoelastic material behavior in conjunction to its impact on temperature-dependent tack. Maximum achievable tack is found to decrease as a function of both degree of conversion and toughener content. Meanwhile, both influencing factors shift the tack maximum towards higher temperatures corresponding to increased flow characteristics attributed to evolving network formation and the incorporation of high molecular weight PES. In terms of absolute tack level and corresponding temperature, probe tack values similar to commercial prepreg systems (∼100 μJ mm−2) are recorded for TGMDA-based formulations containing 10 wt% PES at 20% pre-cure. Model formulations, which have neither been exposed to B-staging nor toughened, show exceptionally high tack below room temperature for all investigated epoxy prepolymers and are therefore not considered processable by automated fiber placement.

Follow the link to the entire article.

- Open Access Artikel verfügbar: Tack of epoxy resin films for aerospace-grade prepregs: Influence of resin formulation, B-staging and toughening - 22. Juli 2022

- Open Access Artikel verfügbar: Adhesion-cohesion balance of prepreg tack in thermoset automated fiber placement. Part 1: Adhesion and surface wetting - 15. November 2021

- Open-Acces-Artikel über Prepreg Tack erschienen: A review of mechanisms, measurement, and manufacturing implication - 8. Juni 2020