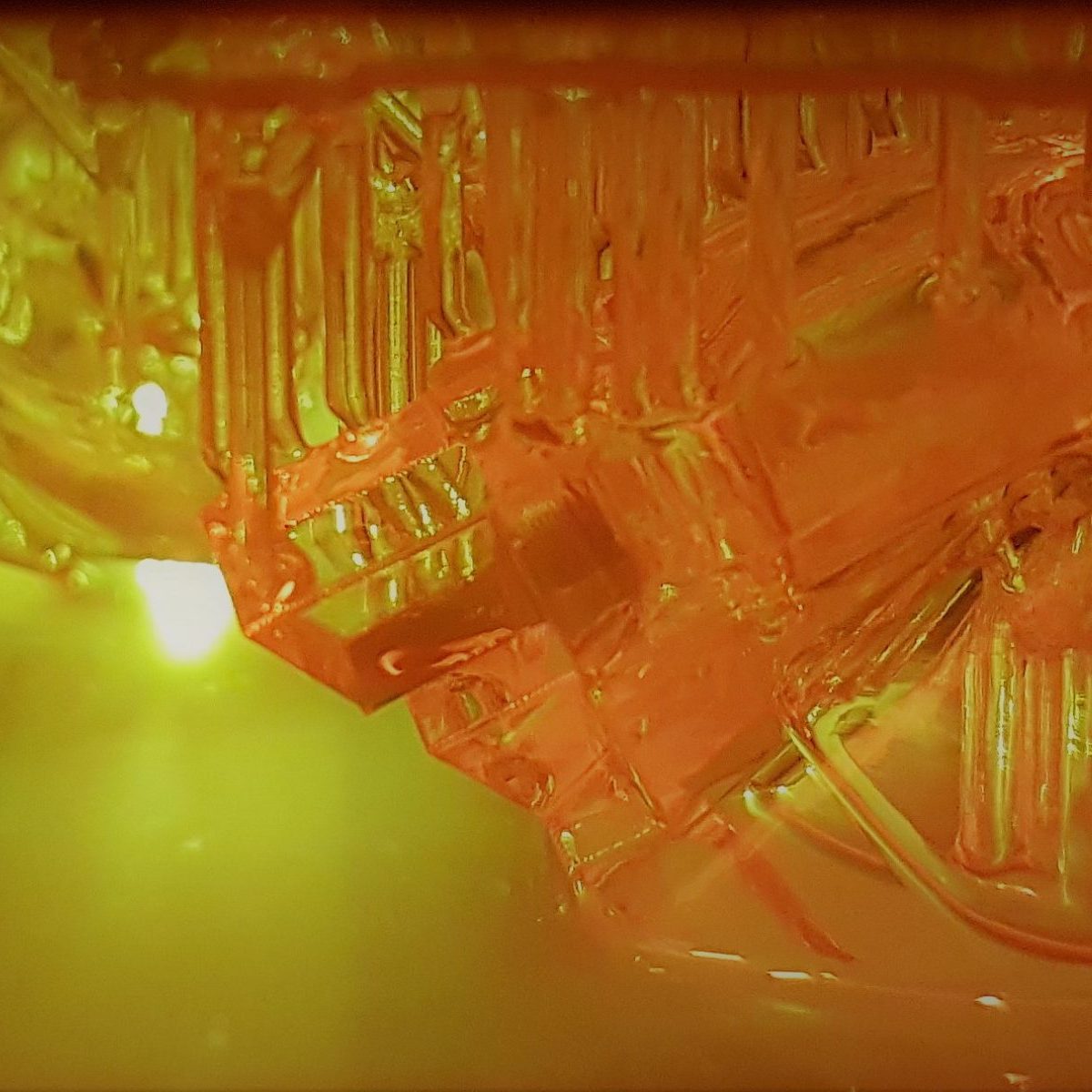

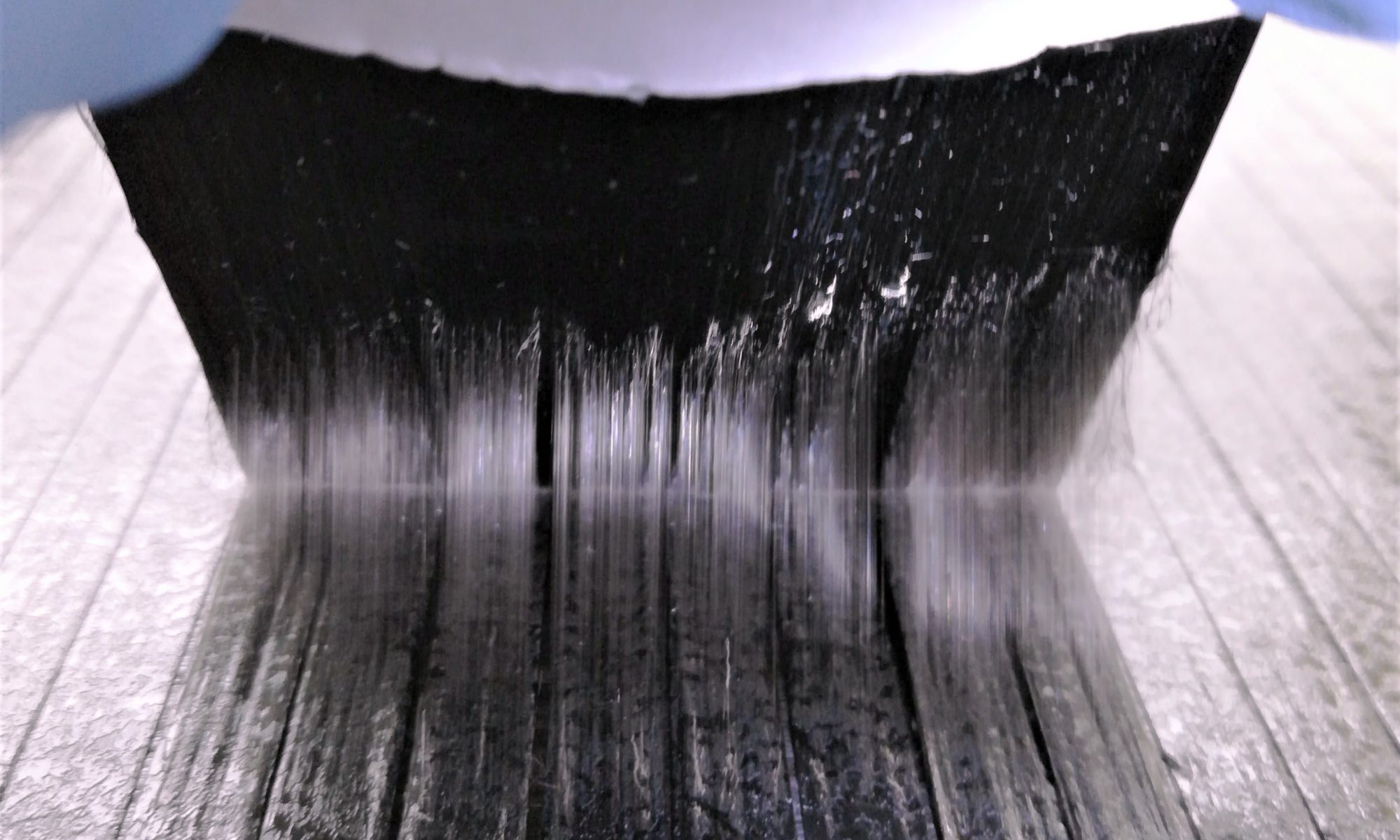

The stickiness of prepregs (tack) is considered a decisive material property for the success of high‐quality composite manufacturing by automated lay‐up processes such as automated fiber placement (AFP) or automated tape laying (ATL). Adverse control of prepreg tack can easily result in laminate defects or machine breakdown, which are highly undesirable considering the tremendous machinery and material costs of these processes. Prepreg tack is governed by a complex interaction of adhesive and cohesive phenomena that are influenced by machine and environmental parameters of the production process as well as by intrinsic properties of the prepreg material itself. This review aims at providing a condensed insight into the current state of research on prepreg tack. Therefore, experimental studies including the discussion of utilized tack measurement methods as well as model approaches to prepreg tack are reviewed. The findings are discussed against the background of fundamental mechanisms, the strong interdependency of influencing parameters and the challenge of translating measured tack data into an enhanced AFP/ATL process stability by process adjustment.

Follow the link to the entire article.

- Open Access Artikel verfügbar: Tack of epoxy resin films for aerospace-grade prepregs: Influence of resin formulation, B-staging and toughening - 22. Juli 2022

- Open Access Artikel verfügbar: Adhesion-cohesion balance of prepreg tack in thermoset automated fiber placement. Part 1: Adhesion and surface wetting - 15. November 2021

- Open-Acces-Artikel über Prepreg Tack erschienen: A review of mechanisms, measurement, and manufacturing implication - 8. Juni 2020